Top 10 Common Fastener Mistakes – and How to Avoid Them

Fasteners may be small, but they play a huge role in the safety, strength, and longevity of every project, from industrial machinery to home DIY builds. Whether you’re assembling heavy-duty equipment or securing a simple joint, the wrong fastener choice or installation method can lead to costly failures.

As a leading nuts and bolts supplier, we’ve seen the most common fastener mistakes — and we’re here to help you avoid them.

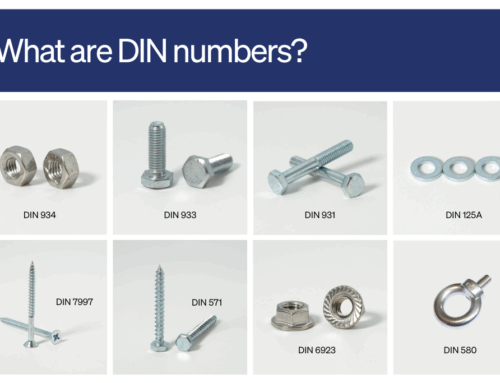

- Using the Wrong Fastener Type

Fasteners are manufactured for different purposes; a wood screw for metal or a coarse-thread bolt in fine-thread applications can lead to stripped threads and weak joints.

How to avoid it:

Always match your fastener to the material and load requirements. Refer to manufacturer charts or consult your supplier for guidance.

- Ignoring Material Compatibility

Mixing materials — like pairing stainless steel bolts with aluminum parts — can cause galvanic corrosion over time.

How to avoid it:

Use fasteners made from the same or compatible materials as the components they’ll join. Stainless steel, zinc-plated, or galvanized options each serve different environments. Not sure how to tell your metals apart? Ask your local supplier for help.

- Over-Tightening or Under-Tightening

Applying too much torque can strip threads or snap bolts; too little torque leads to loose joints and vibration failure.

How to avoid it:

Use a torque wrench and follow manufacturer torque specifications. For critical applications, consider thread-locking compounds or locking washers.

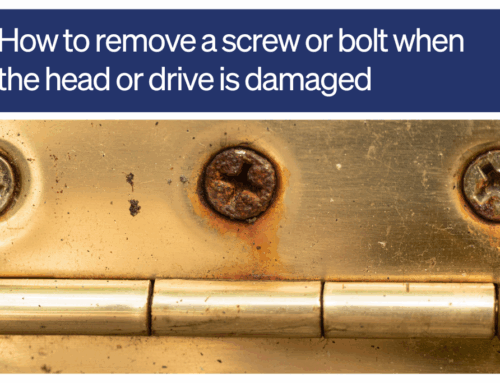

- Reusing Old or Damaged Fasteners

Reusing bolts that have stretched or corroded can compromise safety — especially in automotive or structural applications.

How to avoid it:

Inspect fasteners before reuse. Replace any that show signs of rust, wear, or deformation.

- Ignoring Environmental Conditions

Fasteners exposed to moisture, salt, or chemicals will degrade faster if not designed for that environment.

How to avoid it:

Choose corrosion-resistant fasteners like stainless steel, brass, or galvanized coatings when working outdoors or in harsh environments.

- Failing to Use Washers or Locking Devices

Skipping washers or locking nuts can lead to loosening due to vibration or pressure changes.

How to avoid it:

Use flat washers for even load distribution and locking washers or nylon-insert nuts where vibration is expected.

- Wrong Bolt Length or Thread Engagement

Bolts that are too short may not engage enough threads for a secure hold, while bolts that are too long may bottom out or damage components.

How to avoid it:

Ensure proper thread engagement — typically at least 1.5 times the bolt diameter — and choose lengths that fit your assembly precisely.

- Not Cleaning Threads Before Assembly

Dirty or damaged threads reduce clamping force and can cause galling or thread lockup.

How to avoid it:

Clean threads with a wire brush or compressed air before installation. Lubricate if recommended for the fastener type.

- Using the Wrong Grade or Strength Rating

A Grade 2 bolt won’t perform like a Grade 8 — and substituting them can lead to dangerous failures.

How to avoid it:

Always check the bolt grade and tensile strength requirements. When in doubt, match or exceed the manufacturer’s specification.

- Neglecting Regular Inspection and Maintenance

Even correctly installed fasteners can loosen over time due to vibration, heat, or fatigue.

How to avoid it:

Schedule regular inspections and re-torque fasteners as part of routine maintenance — especially in mechanical or load-bearing applications.

Final Thoughts

Avoiding these common fastener mistakes can save you time, money, and potential safety hazards. Choosing the right nuts, bolts, and washers from a reliable supplier ensures every project is built to last.

If you need expert guidance or high-quality fasteners for your next job, our team is here to help you choose the right products for every application.