Fasteners are the unsung heroes holding our world together, literally. From buildings to furniture, these small but crucial components play a vital role. One key feature in differentiating fasteners is their drive, the feature that allows a tool to engage and turn them. In the UK, various types of drives are prevalent, each serving specific purposes. In this guide, we’ll look at the fastener drives, detailing their characteristics and why those characteristics are necessary

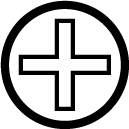

Phillips Drive: The Phillips drive, denoted by a cross-shaped recess, is one of the most widely used types of drives in the UK. It is designed to provide a more significant engagement between the driver and the fastener, reducing the risk of slippage. Recognizing a Phillips drive is straightforward; it resembles a cross or a plus sign.

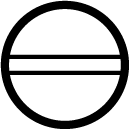

Slotted Drive: The slotted drive, also known as a flat or straight drive, features a simple single slot across the head of the fastener. While it is a traditional and straightforward drive, it is more prone to slipping compared to more modern drive designs. Slotted drives are still common in the UK, especially in applications where precision is not a primary concern

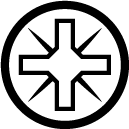

Pozidriv Drive: The Pozidriv drive is an evolution of the Phillips drive, offering improved engagement and reduced cam-out. Identified by its additional set of cross slots at a 45-degree angle to the main slots, Pozidriv drives are commonly found in the UK in applications where higher torque and less slippage are essential

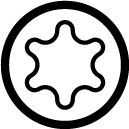

Torx Drive: The Torx drive, characterized by a six-pointed star shape, provides excellent torque transmission and reduced risk of cam-out. Commonly used in high-torque applications, Torx drives are becoming more popular in the UK for their efficiency and reliability

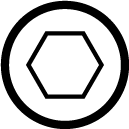

Hex Socket Drive: The hex socket drive, or Allen drive, requires a hexagonal key or wrench to turn the fastener. It provides a high level of torque and precision, making it a popular choice in various applications. Hex socket drives are commonly used in furniture assembly and machinery in the UK.

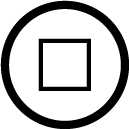

Square Drive: The square drive, recognized by its square-shaped recess, is another popular choice in the UK. It provides good torque transmission and is less prone to cam-out compared to slotted drives. Square drives are often used in woodworking applications and construction.

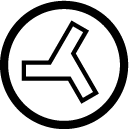

Tri-Wing Drive: The Tri-Wing drive features three wings radiating from the center, forming a triangular shape. This unique drive is less common in the UK but may be encountered in specialized applications.

Whether you’re a professional tradesperson, DIY enthusiast or use fastenings for manufacture, being familiar with these drives will help you identify the fastenings you need and use the correct terminology when ordering or searching online.

Still have questions? Give us a call, we’re always happy to help