In the world of nuts, bolts, and screws, mixing metric and imperial threads is a silent killer – of time, materials, and occasionally, your sanity. It might seem like a harmless shortcut to grab whatever’s on hand, but mismatched threads can lead to damaged components, weakened joints, and costly repairs.

Here’s what you need to know to avoid the pitfalls of mismatched fasteners and how to identify metric vs. imperial threads like a pro.

Why Mixing Metric and Imperial Threads is a Bad Idea

1. They’re Not Compatible

At first glance, metric and imperial bolts might look identical – but they’re anything but. Their thread pitch and diameter measurements are based on entirely different systems:

- Metric: Measured in millimeters (e.g., M6 x 1.0 = 6mm diameter, 1mm thread pitch)

- Imperial (UNC/UNF): Measured in inches (e.g. ¼”-20 = ¼-inch diameter, 20 threads per inch)

Even a small mismatch can lead to:

- Stripped threads

- Cross-threading

- Poor clamping force

- Failure under load

2. It Damages the Threaded Hole

Trying to force a metric bolt into an imperial thread (or vice versa) may feel like it’s working at first — until it chews up the threads and renders the hole useless.

3. It Compromises Safety

In critical applications (think machinery, vehicles, structural fixings), mismatched threads can literally be a disaster waiting to happen. You’re gambling with performance and safety.

How to Identify Metric vs. Imperial Bolts & Screws

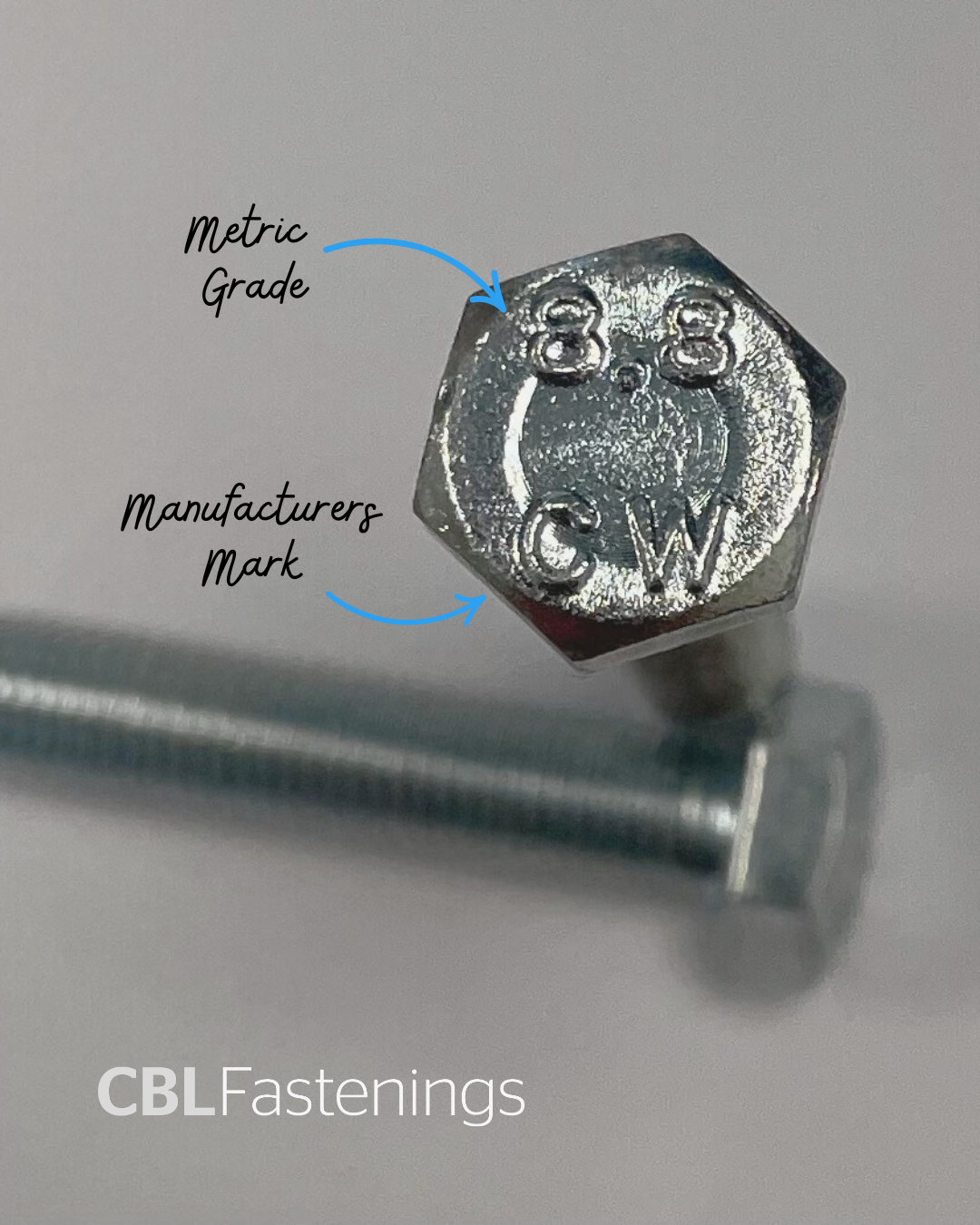

- Check the Head Markings

Metric bolts are graded using a number system (like 8.8, 10.9, 12.9, etc.) that indicates their strength and performance. These grades are standardised internationally (mainly by ISO) and stamped on the bolt head as numbers rather than lines, as with imperial bolts.

| Grade | Marking on Head | Tensile Strength (MPa) | Yield Strength (MPa) | Common Uses |

| 4.6 | 4.6 | 400 | 240 | Light-duty uses (low-stress) |

| 8.8 | 8.8 | 800 | 640 | Automotive, machinery (medium strength) |

| 10.9 | 10.9 | 1000 | 900 | High-stress components, heavy machinery |

| 12.9 | 12.9 | 1200 | 1080 | Extremely high-stress, critical joints |

How to Read Metric Bolt Grades

The number is split into two parts:

- First number = Approximate tensile strength in MPa divided by 100

- Second number = The ratio of yield strength to tensile strength

Example:

- A 10.9 bolt has:

- Tensile strength = 10 × 100 = 1000 MPa

- Yield strength = 0.9 × 1000 = 900 MPa

Additional Info

- Metric bolts also specify property class, thread pitch, and diameter (e.g., M10 × 1.5 – 8.8 means: 10mm diameter, 1.5mm thread pitch, grade 8.8).

- Higher-grade bolts are usually hardened alloy steels, whereas lower grades may be plain carbon steel.

Quick Tips for Identification

- Unlike imperial bolts, metric bolts show the full grade (e.g., 8.8) stamped directly on the head.

- If no grade is visible, assume it’s not high strength (often 4.6 or lower).

- Metric bolts are used worldwide in engineering, automotive, aerospace, and structural applications.

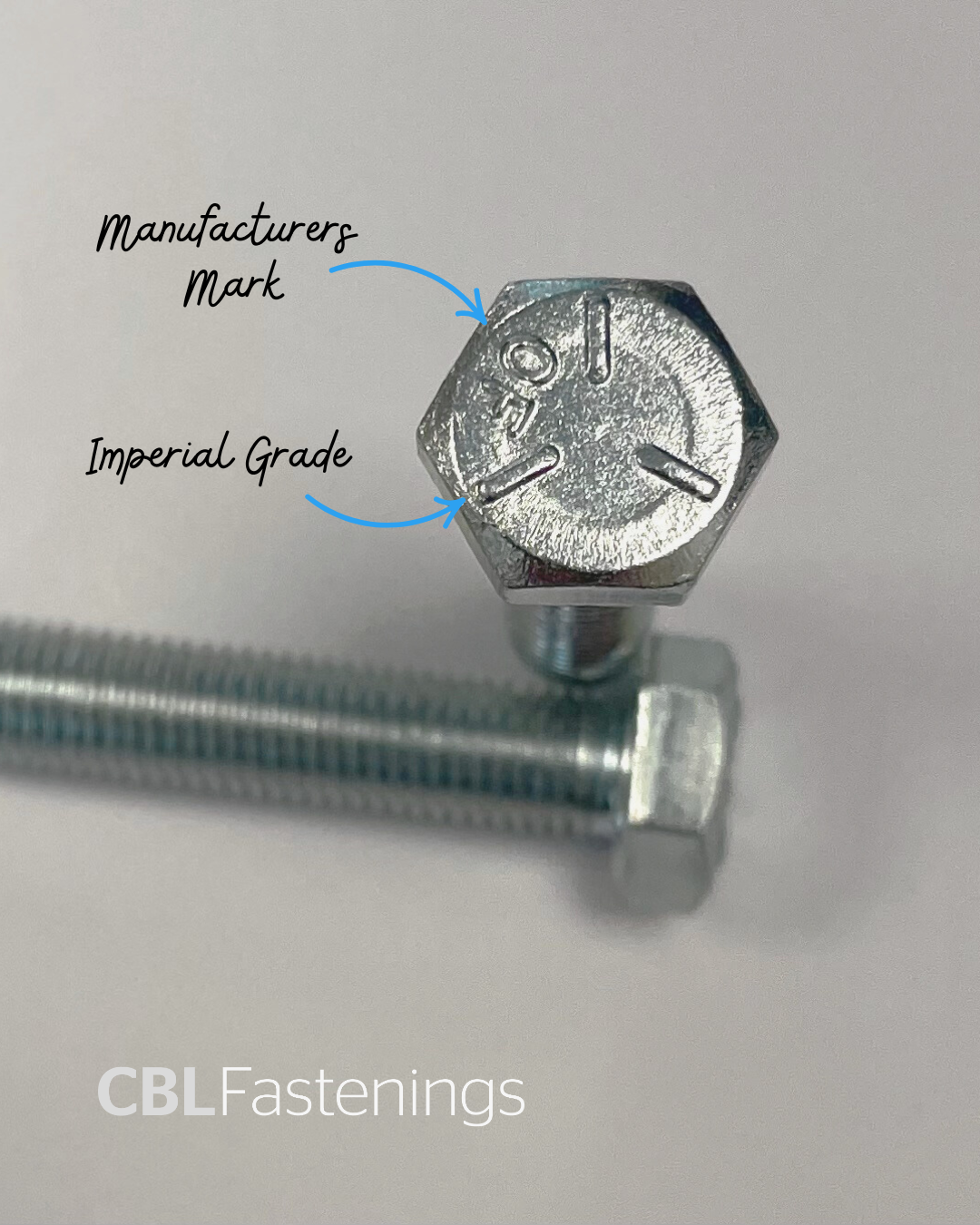

Imperial bolts may have lines or dashes to show their grade.

Common Imperial Bolt Grades (SAE System)

| Grade | Head Marking | Material / Properties | Tensile Strength |

| Grade 2 | No markings or one radial line | Low or medium carbon steel | ~60,000 psi (up to 74,000 psi depending on diameter) |

| Grade 5 | Three radial lines | Medium carbon steel, heat treated | ~120,000 psi |

| Grade 8 | Six radial lines | Medium carbon alloy steel, quenched and tempered | ~150,000 psi |

Understanding the Head Markings

- Radial lines indicate the grade of the bolt.

- Count the lines and add 2 to get the grade.

- 3 lines → Grade 5 (3 + 2)

- 6 lines → Grade 8 (6 + 2)

- Count the lines and add 2 to get the grade.

- No lines generally means a Grade 2 bolt, which is low-strength and not heat-treated.

- Additional symbols or letters may indicate the manufacturer or compliance with specific standards.

Notes:

- Higher grade = stronger bolt, but also more brittle. Use higher-grade bolts only where necessary.

- Don’t mix grades in the same assembly unless specified.

- Imperial bolts are measured in inches (threads per inch – TPI) rather than metric millimeters.

When to Use Each Grade:

- Grade 2: Light-duty, non-critical applications (e.g., household uses).

- Grade 5: Automotive and machinery where moderate strength is needed.

- Grade 8: High-stress applications like suspension systems or heavy machinery.

If you’re supplying or working with fasteners in your business, having a bolt gauge and a head marking chart on hand can be very useful.

- Measure the Diameter

Use a caliper or vernier;

- Metric bolts will measure in mm (e.g., M8 = 8mm diameter).

- Imperial bolts will measure in fractions of inches (e.g., ⅜”, ½”).

- Measure Thread Pitch

- Use a thread pitch gauge or compare against a known fastener.

- Metric thread pitch is the distance between threads (e.g., 1.25mm).

- Imperial threads are measured in threads per inch (TPI) (e.g., 24 TPI).

- Use Thread Charts or ID Tools

Many fastener suppliers offer thread identification kits or printable charts — a worthwhile addition to your toolbox.

How to Avoid Mixing Metric and Imperial Threads

- Separate storage: Keep metric and imperial fasteners in clearly labelled, separate containers.

- Use thread gauges: They’re inexpensive and save tons of guesswork.

- Train your team: Make sure everyone on site or in the workshop knows how to spot the difference.

- Standardise when possible: If you can, stick to one system across a project or workshop to reduce confusion.

- Buy from trusted suppliers: Good suppliers will clearly label sizes, threads, and grades to avoid mix-ups.

Final Thoughts

Mixing metric and imperial threaded fasteners is one of those things that feels harmless… until it isn’t. Whether you’re a seasoned pro or weekend DIYer, taking the time to identify and match your threads properly will save you from expensive mistakes and potential safety risks.

Need help identifying a fastener or building a thread chart for your team? Get in touch — we’re happy to help.